Delivering power with protection: Protecting drive systems to increase renewable energy production

The Company

Canadian Renovations & Restorations Inc. (CR&RI) provides a resource for renewable energy systems including installation, management, monitoring, and maintenance of solar power generators. CR&RI manages, monitors, and maintains commercial rooftop and many dual-axis sun-tracking ground mounted solar generation stations located in local and remote regions of Ontario, Canada. Dual-axis solar generators track the sun east to west and rotate to match the declination of the sun during the day. Solar tracking increases production, and thus revenue, by 40% over fixed tilt solar systems.

![]() Dual-axis solar tracker installation (13.0 kW)

Dual-axis solar tracker installation (13.0 kW)

The Problem

While dual-axis trackers greatly increase solar power production efficiency and revenue, they cost more and are more maintenance intensive than fixed tilt non-moving systems. CR&RI accepted the contract to maintain an existing portfolio of solar generators that were under engineered for the wind loading these trackers would experience. Because of this, solar arrays were shearing motor shafts and stressing gearboxes thus arresting the tracking function and thereby reducing revenue and adding cost to the Owners investment. Compounding the problem, the stations were built in remote locations, and when a solar tracker stopped functioning, it would take as much as 4 to 5 hours to reach and repair the inoperable mechanism.

The solar trackers unplanned downtime was robbing the Owners of revenue and reducing return on investment. A 20-year contract with the Ontario government pays the owners a fixed specific rate for power generation for the length of the contract. Every watt missed is a watt lost in return on the investment of an expensive solar tracker. For the Owners, Canadian Renovations & Restorations Inc. needed a solution that would make the drivetrains of the solar trackers more reliable.

A sheared motor shaft still visible in the slew drive (east to west movement)

A sheared motor shaft still visible in the slew drive (east to west movement)

The Solution

Having endured broken motor shafts for several years, the Owners relied on Canadian Renovations & Restorations Inc. to find a solution that would integrate between the existing motor shaft and the sun tracking drive mechanism of these solar trackers. The motor shaft was constrained in size to match the size of the slew worm drive that operated the east/west bearing movement. The alternative of changing out the slew drive, allowing for a larger motor shaft, required an expensive upgraded slew drive bearing, along with a crane and crew to lift the solar matrix for removal and reinstallation and was cost prohibitive for a portfolio of solar trackers. After much research and discussion, with many companies and their representatives, on this very custom application and requirement, no solution was found until CRRI turned to Hersey Clutch Company for a drivetrain solution. After a long and thoughtful discussion with Dick Hersey, a 1FCDC friction clutch was decided on for the application.

The bidirectional torque limiting friction clutch functioned as a direct coupling between the motor and the gearbox. It was able to prevent excessive forces from wind load force being fed back into the gear box and motor and was able to begin driving the solar panels to face the sun immediately. Downtime was eliminated.

The HCC friction clutch employs a simple design that provides high reliability and achieves greater functionality as far more expensive clutches reviewed by CR&RI. The high function available, at such an economical price point, provided a cost effective retrofit for all their dual-axis solar tracking power generators.

Test fit of the 1FCDC friction clutch with clutch exposed for visibility.

Test fit of the 1FCDC friction clutch with clutch exposed for visibility.

![]() The solar tracker with the retrofitted clutch enclosed.

The solar tracker with the retrofitted clutch enclosed.

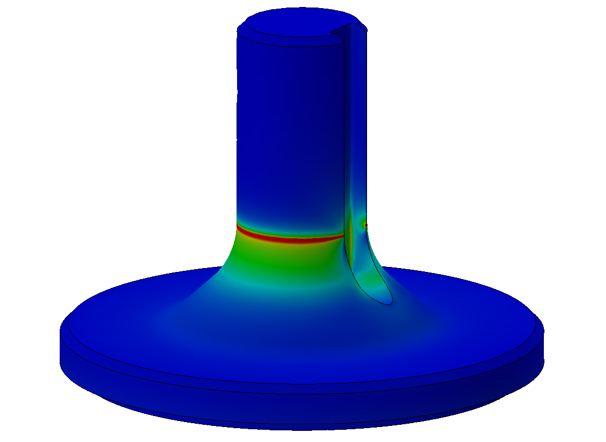

Retrofitting their motor to gearbox connection required a unit that fit within the limited space of their configuration. Our in-house engineering and manufacturing capabilities enabled us to accommodate their specific drive needs with a custom developed output shaft. Using SolidWorks Simulation, we were able to rapidly iterate the design to optimize the output shaft geometry to maximize strength within the small package. We delivered a design suited to their specific conditions within days.

The stress gradient shown for the final custom output shaft.

The stress gradient shown for the final custom output shaft.

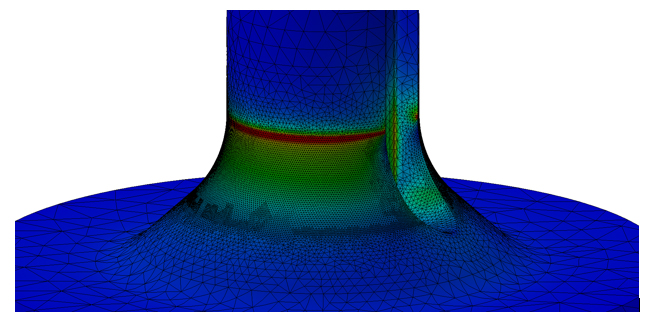

FEA meshing

FEA meshing

Conclusion: Delivering power with protection

Increasing the reliability of the dual axis solar tracker has paid off. Since CR&RI implemented Hersey Clutch Companies friction clutch, there has been zero unplanned downtime because of this issue. The solar trackers have operated as expected and production is commensurate with local solar statistics.

After seeing the dramatic results of using a torque limiting clutch on their test dual-axis solar power generator, Canadian Renovations & Restorations Inc. retrofitted all the solar dual-axis tracker in the same way.